Noocyada CNC-da-rogista ee birta/aluminiumka isku-xidhka dabacsan ee matoorka

Isku-xidhaha daanka ee qaloocan

Xirmooyinka daanka qaloocan ayaa loo isticmaali karaa codsiyo badan waxayna u adeegaan sidii isku xidhka ujeeddo kasta leh.Naqshadeynta aasaasiga ah ee daanka qalooca ayaa u oggolaanaya al awood torque sare ee naqshad is haysta.Ilkaha qalloocan wuxuu leeyahay aag xiriir oo weyn kaas oo siinaya awoodda qulqulka sare, wuxuuna yareeyaa cadaadiska cidhifka.Waxay dejin doontaa axial, radial iyo usheeda dhexe ee khaldan.

Xuddunta waxaa laga soo saaraa agabyo kala duwan oo ay ka mid yihiin: aluminium, cawl, bir, bir, bir sinteed, iyo birta aan lahayn.Walxaha caarada ayaa laga heli karaa doorashooyin durometer oo kala duwan gudaha Urethane & Hytrel.Caaro-caarada waxay ku gudan kartaa xaaladaha wareegga shaqada caadiga ah ilaa wareegyo culus oo ay ku jiraan rarka naxdinta leh waxayna yareyn kartaa gariirka torsional ee nidaamka.

| Qaabka | Cabbirka godka (mm) | Lagu qiimeeyayTorque (Nm) | MaxTorque(Nm) | Xawaaraha ugu badan | Dhexroorka dibadda (mm) | Dhererka (mm) | Dulqaadka Dhaadheer (mm) |

| HS -TCN-14C | 3 ~ 7 | 0.7 | 1.4 | 45000 | 14 | 22 | +0.6~0 |

| HS-TCN-20C-R | 4 ~ 11 | 1.8 | 3.6 | 31000 | 20 | 30 | +0.8-0 |

| HS-TCN-30C-R | 6 ~ 16 | 4 | 8 | 21000 | 30 | 35 | +1.0-0 |

| HS-TCN-40C-R | 8 ~ 28 | 4.9 | 9.8 | 15000 | 40 | 66 | +1.2-0 |

| HS-TCN-55C-R | 9.5-32 | 17 | 34 | 11000 | 55 | 78 | + 1.4 ~ 0 |

| HS-TCN-65C-R | 12.7-38.1 | 46 | 92 | 9000 | 65 | 90 | +1.5-0 |

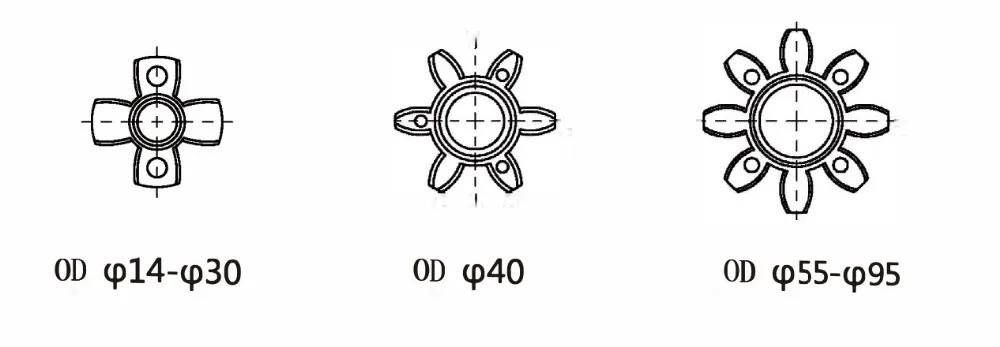

Tilmaamaha Caarada

Isku-xidhka daanka qaloocan waxa ka mid ah laba hub oo bir ah iyo curiye “caaro” elastomeric ah.Caarada ayaa laga heli karaa gudaha

durometers qallafsanaanta kala duwan, mid kasta si fudud loo aqoonsaday by midabkiisa.

| Adag | Midabka | Qalab | Kala duwanaanta heerkulka | Codsiyada |

| 80 Xeebta A | Buluug | Polyurethane | -50 ~+80 .C | qoyaan aad u fiican |

| 92 Xeebta A | Jaalle | Polyurethane | -40~+90 .C | Qoyaanka dhexdhexaadka ah, codsiyada guud |

| 98 Xeebta A | Casaan | Polyurethane | -30 ~+90 .C | Codsiyada torque sare |

| 64 Xeebta D | Cagaaran | Polyurethane | -50 ~+120 .C | Dhaqdhaqaaq sare, heerkul sare |

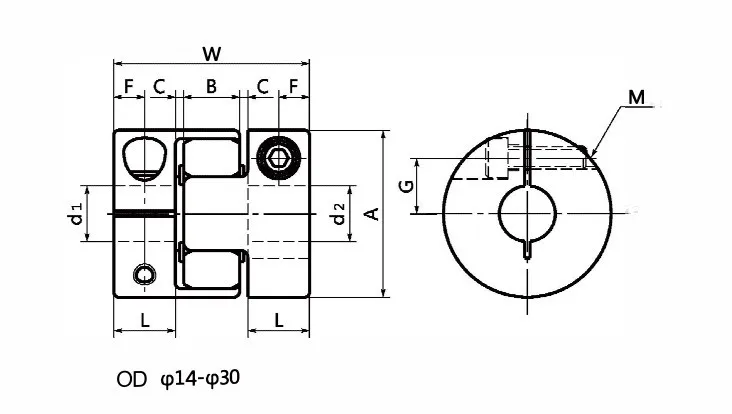

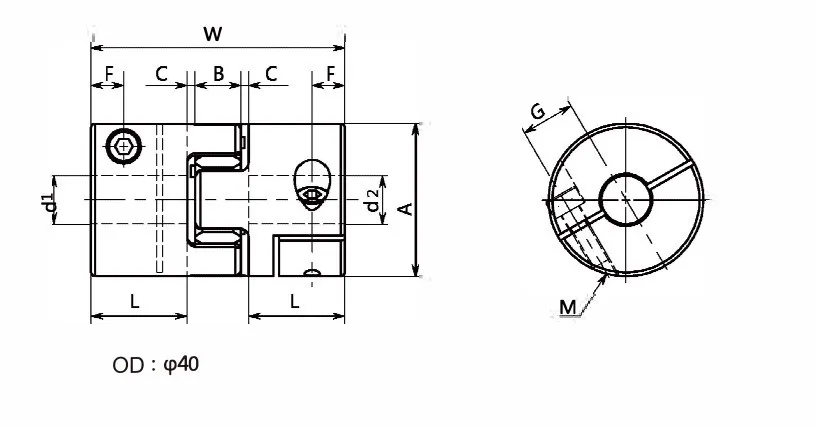

Isku-xidhka cabbirka macluumaadka

| A | L | W | B | C | F | G | M |

| 14 | 7 | 22 | 6 | 1 | 3.5 | 4/5 | M2/M1.6 |

| 20 | 10 | 30 | 8 | 1 | 5 | 6.5/7.5 | M2.5/M2 |

| 30 | 11 | 35 | 10 | 1.5 | 8.5 | 10/11 | M4/M3 |

| A | L | W | B | C | F | G | M |

| 40 | 25 | 66 | 12 | 2 | 8.5 | 14/15.75 | M5/M4 |

| A | L | W | B | C | F | G | M |

| 55 | 30 | 78 | 14 | 2 | 10.5 | 20/21 | M6/M5 |

| 60 | 35 | 90 | 15 | 2.5 | 13 | 24/25 | M8/M6 |